|

|

|

|

| Combating

the Odor:

Lagoons have been a popular storage technique of the past. It was believed that removing the majority of the manure from the swine living environment would improve the living conditions of the hogs. However, this approach has not curbed the odor problem and has not significantly improved the swine living environment. Also, the issue of ground water contamination and the mere sight and smell of these outdoor manure pools has pushed manure storage underneath the hog facility. In-house storage is now common among many new hog buildings. With respect to odor, the primary idea behind in-house storage is "out of site-out of mind". This storage technique helps contain a few more odors; however, since the manure is directly underneath the pigs, pit ventilation is needed to remove the potentially poisonous odors. This ventilation is beneficial for the hogs but becomes problematic for neighbors who have to endure the upwind operation. With in-house storage the most common technique to combat the odor is to dump pit additives to eat the odor-producing bacteria. Many farmers have tried pit additives and they all work to some degree, but the odor is still present. Currently this is the best solution, next to correctly balancing the hog’s diet, to odor control that anybody has commercially developed. Ozone

Distribution System:

There are many variables that need to be considered when installing this ozone distribution system. Here are just a few.

Formation

and Uses of Ozone:

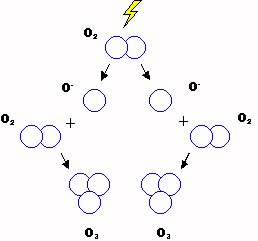

How Ozone is Created:

Ozone is extremely unstable and easily reacts with other chemicals. This reaction is called oxidation. Oxidation occurs when electrons are exchanged between molecules, which changes their molecular structure. The most familiar type of oxidation occurs when iron is exposed to air. The oxygen in the air reacts (oxidizes) with the iron to produce what is commonly known as rust. The presence of oxygen has changed the chemical structure of the iron. Ozone has the same oxidizing effect but oxidizes many more substances at a faster rate. Uses:

Application

of Ozone in Swine Facilities:

In these ozone distribution systems, an air dryer dries the air to -100? F dew point. Next, an oxygen concentrator removes the excess nitrogen and increases the oxygen concentration to 95%. This high concentration oxygen enters the ozone generator that creates the ozone. The ozone is pushed in front of a distribution fan where an engineered system of PVC tubing and holes help distribute the ozone. The ozone eventually permeates the air space in the building while oxidizing odors, bacteria, mold and viruses. Ozone is also circulated by natural air currents and eventually settles directly above the pit preventing many potentially harmful odors from reaching the hogs. The ozone significantly reduces the ammonia and hydrogen sulfide odor that the hogs produce. The ozone is constantly oxidizing these odors. The ozone also keeps the feed fresher since mold is prevented from growing. Bacteria and viruses are reduced since ozone is oxidizing and destroying many of these pathogens. Ozone is a 24-hour disinfectant! The next section contains a testimony from Picket Fence Farms. It explains the positive results that they have seen from the ozone system. It also explains the diseases that have been reduced or eliminated on the Farm from many years of ozone use. |

|

|

|

|

| hog performance recorded over 35 days |

| August-September | December-January |

| Avg. wt Pigs In (lbs) | 12.00 | Avg. wt Pigs In (lbs) | 13.00 | |

| Avg. wt Pigs Out (lbs) | 39.94 | Avg. wt Pigs Out (lbs) | 50.00 | |

| Total Head | 1,449 | Total Head | 786 | |

| Total Head Sold | 1,426 | Total Head Sold | 781 | |

| Avg. Death Loss | 1.59% | Avg. Death Loss | 0.64% | |

| Total Pig Days (TPD) | 50,521 | Total Pig Days (TPD) | 27,659 | |

| Total Feed Consumed (lbs) | 63,621 | Total Feed Consumed (lbs) | 41,450 | |

| Avg. Daily Consumption (lbs)* | 1.26 | Avg. Daily Consumption (lbs) | 1.50 | |

| Total lbs Produced | 39,572 | Total lbs Produced | 28,832 | |

| Avg Daily Gain (lbs/day)** | 0.78 | Avg Daily Gain (lbs/day) | 1.04 | |

| Avg. Feed Conversion*** | 1.61 | Avg. Feed Conversion | 1.44 |

|

|

|

|

| We would like to let you know what we

have experienced in the last three years while using ozone. All our

buildings have full pits and pit ventilation. We will break down

the information we have by starting with the farrowing rooms.

Farrowing:

Nursery:

Finisher:

We are excited about what ozone has done

for us and think you will be too.

|

| Benefits seen in the Farrowing House:

75% decrease in Ecoli scours

The sows consumed up to 20% more feed because of better air quality. With better feed consumption the sows are more comfortable, which is the main reason for less pigs laid on and also the increase in the pigs weaning weight. The increase of better air quality and the ability for ozone to oxidize or kill bacteria accounts for the decrease in Ecoli scours and other scours and also gives noticeably cleaner, pinker, and healthier looking pigs. Benefits seen in the Nursery: 100% decrease or no signs of PRRS

Weight gains in the nursery went from 0.6 lbs. to 1 lbs. or more average daily gain. Death loss went from 2.6% to less than 0.6%, and the all-in/all-out pig flow did not have to be maintained. Without ozone and continuous flow, the death loss climbed to 25% or more at times. Infection of pig’s ears, etc. (which came from the fighting due to commingling) healed faster and the pigs skin stayed noticeably pinker and healthier looking with the ozone. Benefits seen in the Finisher: 100% decrease or no signs of PRRS

Pigs in the finisher showed all of the

same benefits as seen in the nursery but we do not have a lot of the groups

recorded to give in-depth account. Visual signs were no rhinitis

(with 30% for more before ozone with bull nose), and no sign of PRRS or

Pneumonia.

|